What are the types of precision casting?

Precision casting refers to getting The general term for the processing technology of castings with accurate specifications. Compared with the traditional sand casting process, the casting specifications obtained by precision casting are more accurate and the surface smoothness is stronger. It includes: investment casting, porcelain casting, metal casting, working pressure casting, and lost foam casting.

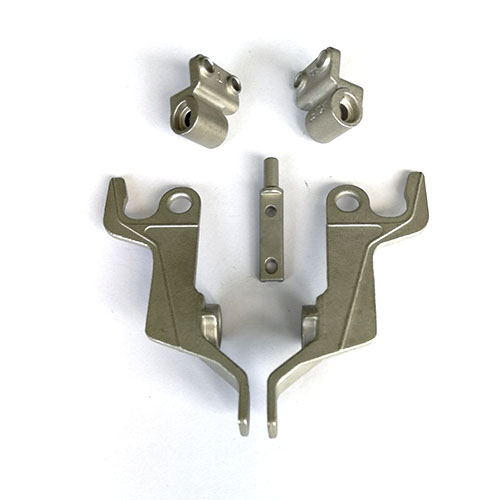

Precision casting is also called lost wax casting. Its products are high-precision, complex, and close to the finished parts. It can be used immediately without production or processing. It is an advanced technology that is near net shape.

One of the more common ones is investment casting, also called lost wax casting: using suitable investment raw materials(Such as paraffin wax) to produce investment molds; the process of repeatedly dipping fireproof architectural coatings and fire-resistant sand on the investment molds to harden the shell and dryness; then melt the internal investment molds to obtain a cavity; baking type Shell to obtain sufficient compressive strength, and burn the remaining investment raw materials; metal composite materials necessary for pouring; condensation and cooling, sand removal after molting, and then obtain high-precision finished products. According to the product, it is necessary to carry out heat treatment process, cold drawing and surface treatment.