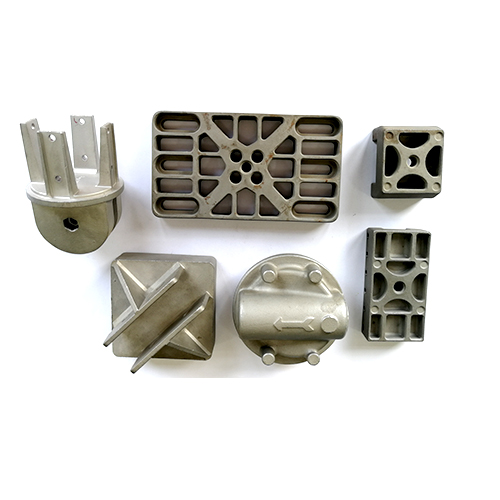

The principle of precision casting gray iron processing

The raw material gray iron used in precision casting gray iron processing refers to cast iron containing flake graphite, which mainly becomes iron, carbon, silicon, manganese, sulfur, and phosphorus, and its output accounts for more than 80% of the total output.

The carbon content of gray iron parts is higher, about 2.7%-4%, which can be said to be carbon steel plus flake graphite. According to the different matrix structure, gray iron can be divided into three categories: ferrite plus flake graphite , Ferrite and flake graphite.

Mechanical properties of precision casting gray iron:

The mechanical properties of gray iron machined parts are related to the matrix structure and graphite morphology. The flake graphite and the gray iron matrix split severely, and the sharp corners of the graphite are prone to stress concentration, which makes the gray cast iron have tensile strength and plasticity.

Hardness and toughness are much lower than steel, and its compressive strength is equivalent to steel. It is also a cast iron with poor mechanical properties among ordinary cast irons. In addition, the matrix structure has a certain influence on the mechanical properties of gray cast iron, and the ash slag is also different.

The graphite sheet used for casting is thick, with low strength and hardness, and the pearlite matrix gray cast iron with less application. The graphite sheet is fine, with high strength and hardness. It is mainly used for the ferrite pearlite of important castings.

Compared with pearlite gray cast iron, gray iron graphite flakes are slightly thicker, and its performance is not as good as pearlite gray cast iron. Pearlitic gray iron additives are mostly used in the precision casting industry.

Other characteristics of gray iron;

Gray iron has good castability, shock absorption, wear resistance, and corrosion resistance, and is a commonly used metal part.

Heat treatment process of gray iron parts:

1. Relieve internal stress annealing.

2. Annealing to improve machinability.