Common casting method in foundry industry-dewaxing casting method

There are many casting methods in the mechanism design,Dewaxing casting methodThat is one kind. The dewaxing method is also called the "investment method". Used to make Buddha statues in the past, it is now used to make various products and parts. For example, some familiar products, such as rings, connecting rods, cranks and other parts, are also widely used.

Dewaxing casting methodGenerally include the following steps:

1. Scrape the wax to make a prototype.

2. Harden the prototype with foundry sand.

3. Melt the wax to form holes.

4. Pour molten metal into the cavity.

Take off-wax casting as an example of casting ring. The prototype material of the ring is "wax", so it is easy to cut. Use special tools to scrape wax by hand to make prototypes. Now it is also possible to design 3DCAD, CG and other prototypes on the PC, and then use 3D printing to make the prototypes.

Subsequently, gypsum was used to solidify the prototype, melt the wax, and form a cavity. Metal is injected into the cavity to form a ring.

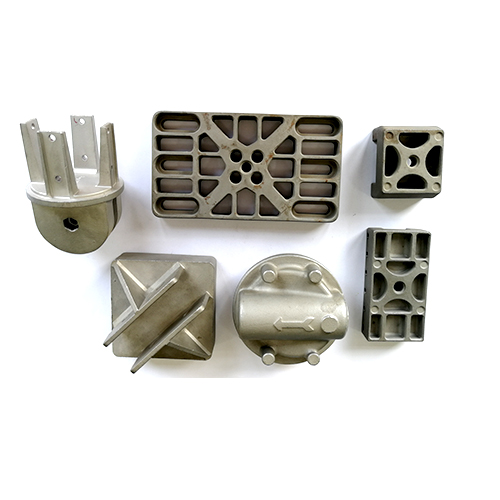

The dewaxing method is a kind of casting, which can form more complicated shapes than casting, and has higher dimensional accuracy.

For mass-produced products, dewaxing casting requires the use of "molds" for prototype manufacturing. Since the mold is a metal mold, it is cut out by a machine tool. Because it is a wax mold, the cost is lower than that of a die-casting mold that requires high strength.

1. Press the wax into the mold to make a "prototype".

2. After the prototypes are in place, connect multiple prototypes to metal channels called "runners". Into the shape of a tree

3. Cover the trees with a refractory layer. In order to make a high-thickness mold, the coating is repeated 5 or 6 times.

4. Dewaxing casting uses high-pressure steam to heat the mold to melt the wax and form a cavity in the mold.

5. Bake the mold hard. (Baking is to put ceramics and other particles in a kiln, and then combine these particles. Also known as baking and sintering).